LeClaire Manufacturing is your one-stop source for tool and die manufacturing services. We use the highest-quality materials for high-quality tool-making because the highest-quality tools make the highest-quality castings. Our skilled design engineers, state-of-the-art modeling software, and our commitment to using the best materials separate LeClaire’s tool-making services from those of our competitors.

Why Choose LeClaire as Your Tool & Die Maker?

- We’ve been serving the industry since 1966.

- We emphasize quality craftsmanship.

- We’re a family-owned and operated business.

- We are ISO 9001:2015 certified.

- We have a 50,000 sq. ft. facility in the heart of the Midwest.

Learn more about LeClaire Manufacturing

Our Tool and Die Services

Tool and Die Design and Engineering

We bring more than 125 years of experience to our die design services. By leveraging the latest in software and technology, we can combine innovation with experience to provide die engineering services for a wide range of tooling options: Blank dies, transfer die, line dies and progressive dies.

Tool and Die Simulation and Validation

Our tool and die designers and engineers work in partnership with your team to simulate tooling designs using state-of-the-art technology. As a result, we can ensure your die design or tooling will withstand the rigors of production.

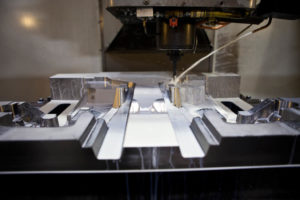

In-House Tool Making

Our master toolmakers are highly skilled craftsmen who make dies, molds, machine tools, cutting tools and more. We build tooling and fixtures in our full-service pattern and die shop in Bettendorf, Iowa, where we take pride in precision tool manufacturing.

Tool Maintenance and Repair

Maintaining your machining tools is the key to protecting your investment and to preserving the quality of your parts. LeClaire offers tool repairs and replacement parts for tools and dies we manufacture, along with tool history documentation.

Get a Quote on Tool and Die Making

Contact us today for a quote; we’ll ask a few questions about your project so we can provide a personalized quote.

Advantages of Tool and Die Manufacturing

Perfect For High-Volume Production

Because the molds created for die casting are made of metal, they can withstand the rigors of long production runs better than some other casting techniques.

Precision is key

Tool and die manufacturing allows for tighter and closer tolerances through the meticulously designed metal molds.

Die casting also produces smoother surfaces when compared with other casting processes.

Allows for added complexity of parts cast

When you cast apart, you can create complex net shapes, including external threads and complex internal features with minimal draft angles—minimizing secondary operations.

Die casting can also produce components with thinner walls and with various wall thicknesses compared to some other processes.

Combine multiple parts into one

With the added complexity that die casting allows, multiple parts can sometimes be combined into one. This reduces the steps needed to assemble the finished product, reducing labor costs.

Read more about the advantages of die casting

Is Die Casting Right for You?

Want to compare your different casting options? Then read more about the strengths of different aluminum casting methods