Aluminum Sand Casting Services

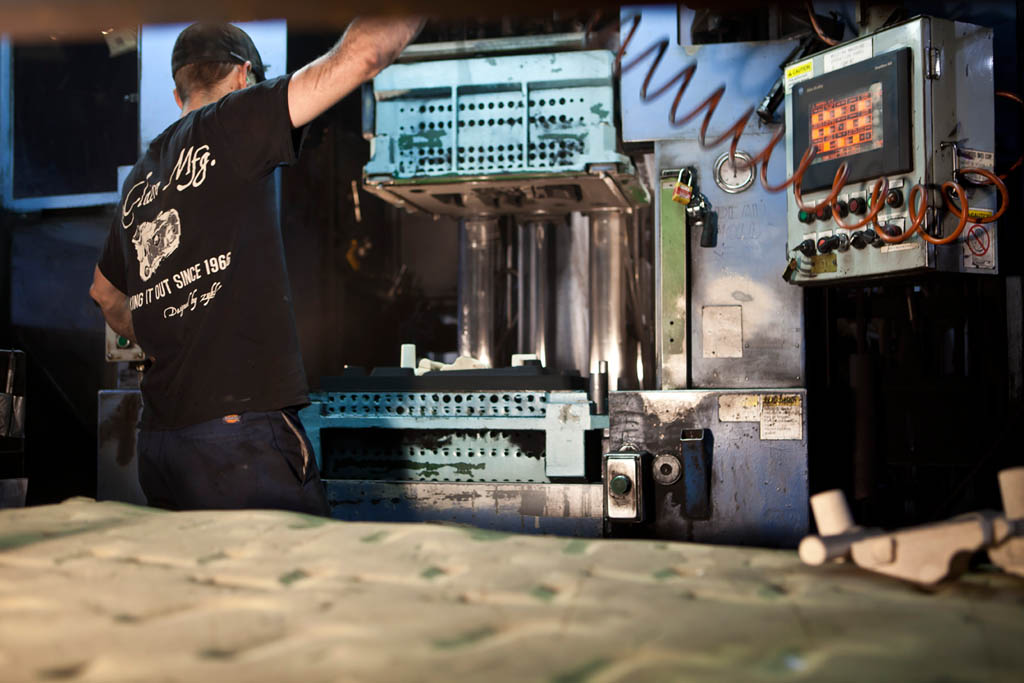

LeClaire Manufacturing in Bettendorf, Iowa, casts and machines simple to complex aluminum sand castings and permanent mold castings. With a focus on automation of our manufacturing processes and controls, we lead the foundry and machining industry in quality, consistency and on-time delivery of aluminum sand casting and machining.

Read More About …

What Is Sand Casting?

Sand casting is a method of producing metal pieces from a mold made of tightly packed and bonded “sand.” The mold is formed around a pattern and then molten metal is poured into the mold in order to produce the finished part.

What Is The “Sand” In Sand Casting Made From?

While it is useful to think of this sand as the kind you might find at the beach, this material has several components. The primary one is a fine, silica-based particulate, but water and a bonding component typically called clay are also part of the mixture.

What Steps Go Into The Sand Casting Process?

The process works this way:

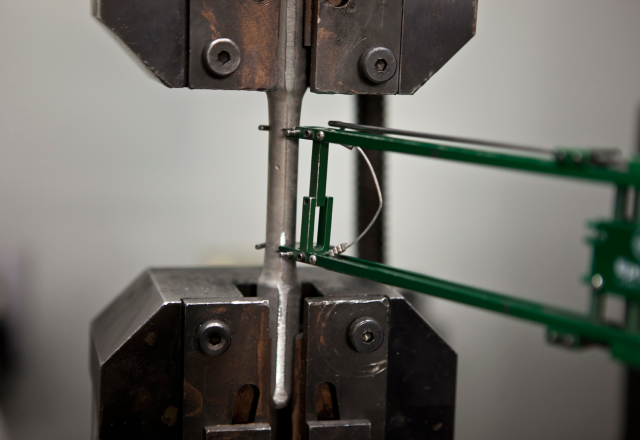

- We create a pattern in the shape of the part. The patterns can be made from a variety of materials and can be very intricate in design.

- The sand is poured, packed and bonded around the pattern to form a cavity (in two halves). We then combine the halves to form the mold. We also form one or more “runners” in the mold. These are the openings through which the metal will enter the mold.

- We pour molten metal material into the mold through one or more runners.

- The metal cools and solidifies.

- We break the sand mold away and remove the finished part.

What are the Benefits of Aluminum Sand Casting?

- Aluminum is a light-weight and strong material. In many industries, keeping the total weight of the final product down is essential. Aluminum provides a lighter alternatives to other metals sometimes used in casting.

- Readily available raw material. Aluminum, the most abundant metal in the earth’s crust, is not in short supply.

- It’s a cost-effective casting process. The sand used in the casting process is simple to form into molds, and after production is done, we break it down and use it again. This reduces raw material and other costs in comparison to other casting methods.

- The simplest and most versatile aluminum casting method. The only limits of sand casting involve the kind of patterns that you can create. This is especially true when dealing with a company skilled in the use of sand casting cores like LeClaire.

- High degree of tooling flexibility to accommodate design changes. Because the tooling process is less cumbersome than other methods, sand casting can produce one of the fastest turnarounds between receiving changes and production.

- Ideal for manufacturing scale-up. Need a prototype or parts for testing? Between the lower costs and the efficient tooling process, sand casting provides you with an efficient means to get the aluminum parts or equipment you need.

- Ideal for low production applications. While sand casting molds aren’t always ideal for massive production runs, they are an excellent lower-cost alternative for smaller runs. Their ease of creation and versatility give sand casting big advantages.

Is Sand Casting Right for You?

Want to compare your different casting options? Then read more about the strengths of different aluminum casting methods

Which Industries Are Served by Aluminum Sand Casting?

Aluminum sand castings has applications in a wide range of industries, including aerospace and defense; agriculture; automotive; energy; marine; medical; mining; and fluid management. Below are some of the applications of our casting services across leading industries.

Consumer Goods

From appliance parts to aluminum cookware to lawn care equipment, LeClaire’s sand casting capabilities are a perfect fit for the consumer home goods industry. Leading manufacturers of merchandise found in marine engines, motorcycles, snow mobile, and grill bodies turn to LeClaire’s for aluminum casting services.

Agriculture

Agriculture applications for our casting capabilities include measuring and control devices, valves, and field equipment parts. Our sand casting services are up to the challenge of manufacturing agricultural parts. Whether it is pickers and spreaders, ag waste removal equipment, tractor parts, or other farm equipment, we have you covered.

Military/Defense Applications

We are proud to serve customers in the defense industry. From helicopter parts to flight control equipment, from missile launch technology to Special Ops field equipment, the military applications of our casting capabilities are wide-ranging.