A Quality Manufacturing Process Makes Quality Castings

When it comes to quality manufacturing, LeClaire rises above the competition. We build the quality into the part, not inspect it out of the part. Utilizing various quality tools, LeClaire Manufacturing ensures that our processes are capable of producing your castings on a consistent basis. Our overall process is as follows:

- Start with the initial design

- Make great tools

- Produce the casting using the latest, state-of-the-art machines

- Heat treat the casting

- Finish the casting to your specification

- Machine the casting as you require

Our fully staffed quality team is led by our quality manager, who previously worked at a Fortune 100 company. The team utilizes:

- FARO® arms with laser scanning

- CMM (coordinate measuring machine) equipment with probing capabilities

- Automated straightening techniques

- Poka-yoke engineering strategies to prevent human error

- Lean foundry and machining techniques

- Dunk and pressure decay leak-testing

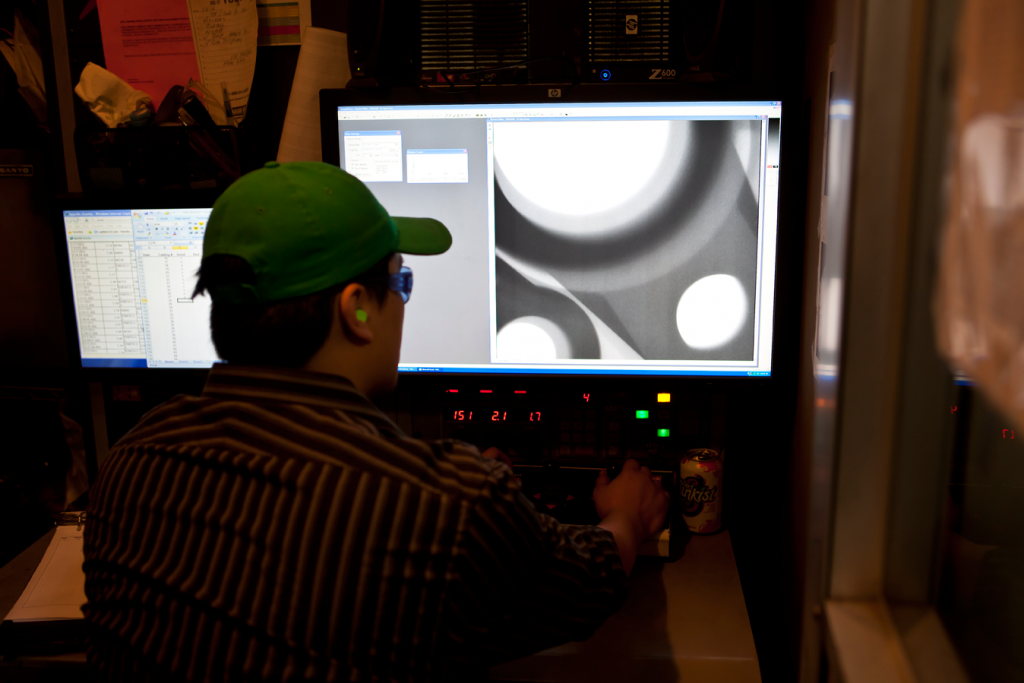

- Digital, real-time x-rays

ISO 9001:2015 and ISO 14001:2015 Certified

LeClaire Manufacturing has met the requirements of ISO 9001:2015 and ISO 14001:2015 for the manufacture of sand cast and permanent mold aluminum alloy castings and machined parts.

To view our ISO 9001:2015 certificate, please click here.

To view our ISO 14001:2015 certificate, please click here.